Dediyasan, Mahesana, Gujarat

- GST NO. : 24AANCM6089K1ZT

Vibrating Equipment

Leading Manufacturers and Wholesaler of Flat Vibrating Feeder, Heavy Duty Vibrating Screen, Multi Deck Vibrating Screen, Tubular Vibrating Feeder, Vibrating Furnace Charger and Vibrating Grizzly Feeder from Mahesana.

| Business Type | Manufacturer, Supplier |

| Driven Type | Electric |

| Color | Available in Many Colors |

| Automatic Grade | Automatic |

| Application | Feeding Material |

| Certification | CE Certified |

| Voltage | 220V |

| Warranty | 1 Year |

| Country of Origin | India |

Preferred Buyer From

| Location | Anywhere in India |

| Business Type | Manufacturer, Supplier |

| Finishing | Polished |

| Automatic Grade | Automatic |

| Power Source | Electric |

| Usage | Industrial |

| Certification | ISI Certified |

| Voltage | 440V |

| Country of Origin | India |

Preferred Buyer From

| Location | Anywhere in India |

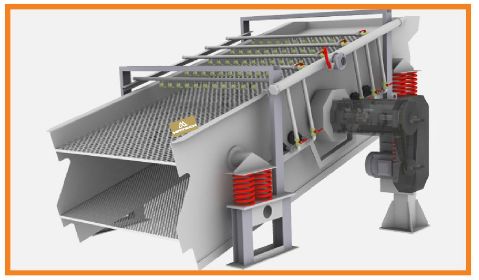

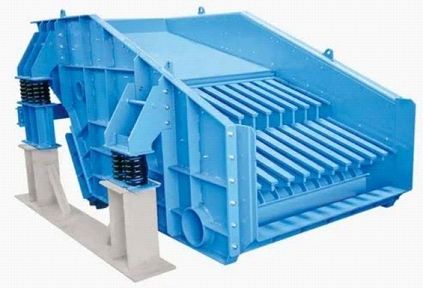

The Heavy Duty vibrating screen (Circular motion) is widely used in metallurgy, mine, coal and construction industry. The eccentric vibration exciter is driven by a universal coupling or flexible coupling jointed motor which does not vibrate simultaneously. The vibration force is adjustable. The damping device is fabricated by rubber spring or composite spring.

| Business Type | Manufacturer, Supplier |

| Material | Stainless Steel, Iron |

| Automation Grade | Automatic |

| Application | Industrial |

| Voltage | 240 V |

| Warranty | 1 Year |

| Country of Origin | India |

Preferred Buyer From

| Location | Anywhere in India |

| Business Type | Manufacturer, Supplier |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Application | Feeding Material |

| Certification | CE Certified |

| Voltage | 380V |

| Warranty | 1 Year |

| Country of Origin | India |

Preferred Buyer From

| Location | Anywhere in India |

| Business Type | Manufacturer, Supplier |

| Automatic Grade | Automatic |

| Power Source | Electric |

| Certification | CE Certified |

| Voltage | 380V |

| Warranty | 1 Year |

| Country of Origin | India |

Preferred Buyer From

| Location | Anywhere in India |

Our assortment of vibrating equipments also includes Furnace Charger, which provides an effective solution to high labor cost and risk faced by furnace operators during foundries, melting shops and others. Available in customized options, our vibratory furnace charger is manufactured using high grade raw material.

We offer Vibratory furnace charger (VFC) in various capacities. A Self bottom opening bucket is provided to charge the vibratory charger. This bucket will carry the charge material of required ratio, directly from the stock yard and place it on the charger structure. The bottom opening door arrangement will automatically open when it placed on the feeder structure and the Raw material falls in the vibratory trough. The raw material will then moves to the furnace when it operates. The advantage of this vibratory furnace charger is that the charge floor is neat and clean. No man power required to charge the furnace. The vibratory charging system is equipped with a variable drive PLC and control panel that helps to charge the raw material to the furnace gradually or bulk. Our VCF (vibratory furnace charger) has been appreciated for its functionality and its ability to reduce charging time and hence enable to enhance.

| Business Type | Manufacturer, Supplier |

| Driven Type | Electric |

| Color | Available in Many Colors |

| Application | Feeding Material |

| Certification | CE Certified |

| Voltage | 220V |

| Warranty | 1 Year |

| Country of Origin | India |

| Capacity | 400-800mm |

Preferred Buyer From

| Location | Anywhere in India |

The nar-rcco-m Vibrating Feeder is a kind of linear direction feeding equipment. It can send shaped and granule materials into crusher evenly, timely and continuously as well as screen the materials roughly. The vibrating feeder is widely used in crushing and sieving production line such as metallurgy, building material, chemical industry, coal, mining and grinding industry.

Application : Widely used in hydropower industry, building Materials,metallurgy, mining, gravel field, chemical industry, crushing, screening production line, etc

Features :

- Smoothly vibrating and long service life

- Vibrating force adjustable, easy to operation.

- Low noise and power consumption

- Simple structure, easy to maintenance.

Working Principle

Vibrating feeder is made of vibrating frame, spring, vibrator, motor vibrating device and motor. The vibrator consists two fixed eccentric shafts whose gears are jogged. When installation, the two gears must be jogged according to the sign. By drive of the motor, the two eccentric shafts start rotating to generate a linear huge power which forces the feeder to vibrate back and forth. Through the vibration, The materials will slip and sling on the funnel, moving forward, when the materials pass the screening part, smaller material will fall down, avoiding the further crushing, so screening purpose is reached.

Matech vibrating grizzly – pre-screens with unbalance motors are used for extraction under hopper and for separating the product in a processing line. This vibration is used as the power to make the material slide on the material chute and drop so that the material moves forward continuously. As a result, material feeding purpose is realized. When the material passes the screen bars of the chute body, smaller pieces of material will drop from the gaps between the screen bars and not enter the next breaking procedure. In this way, material screening result is achieved.